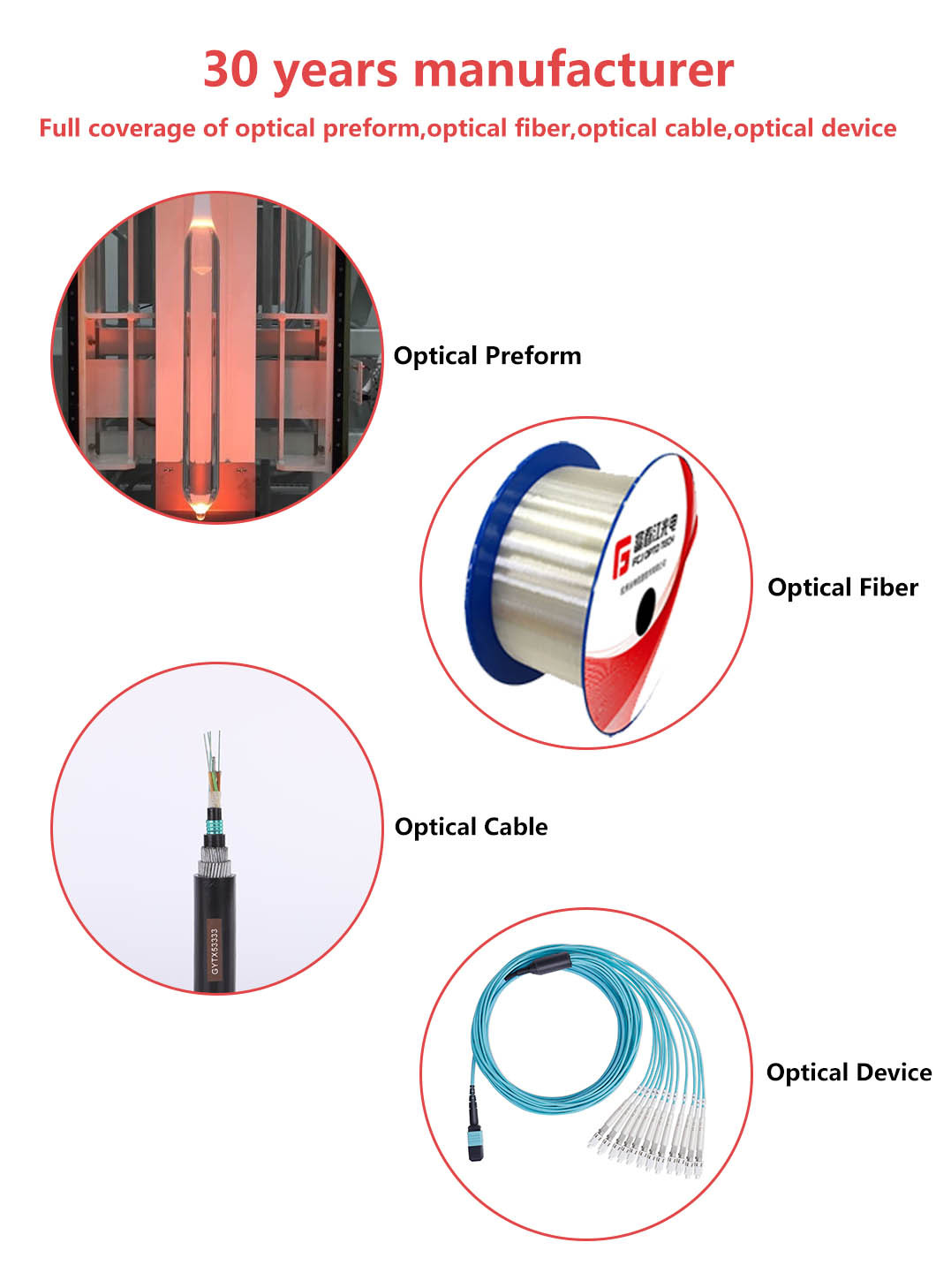

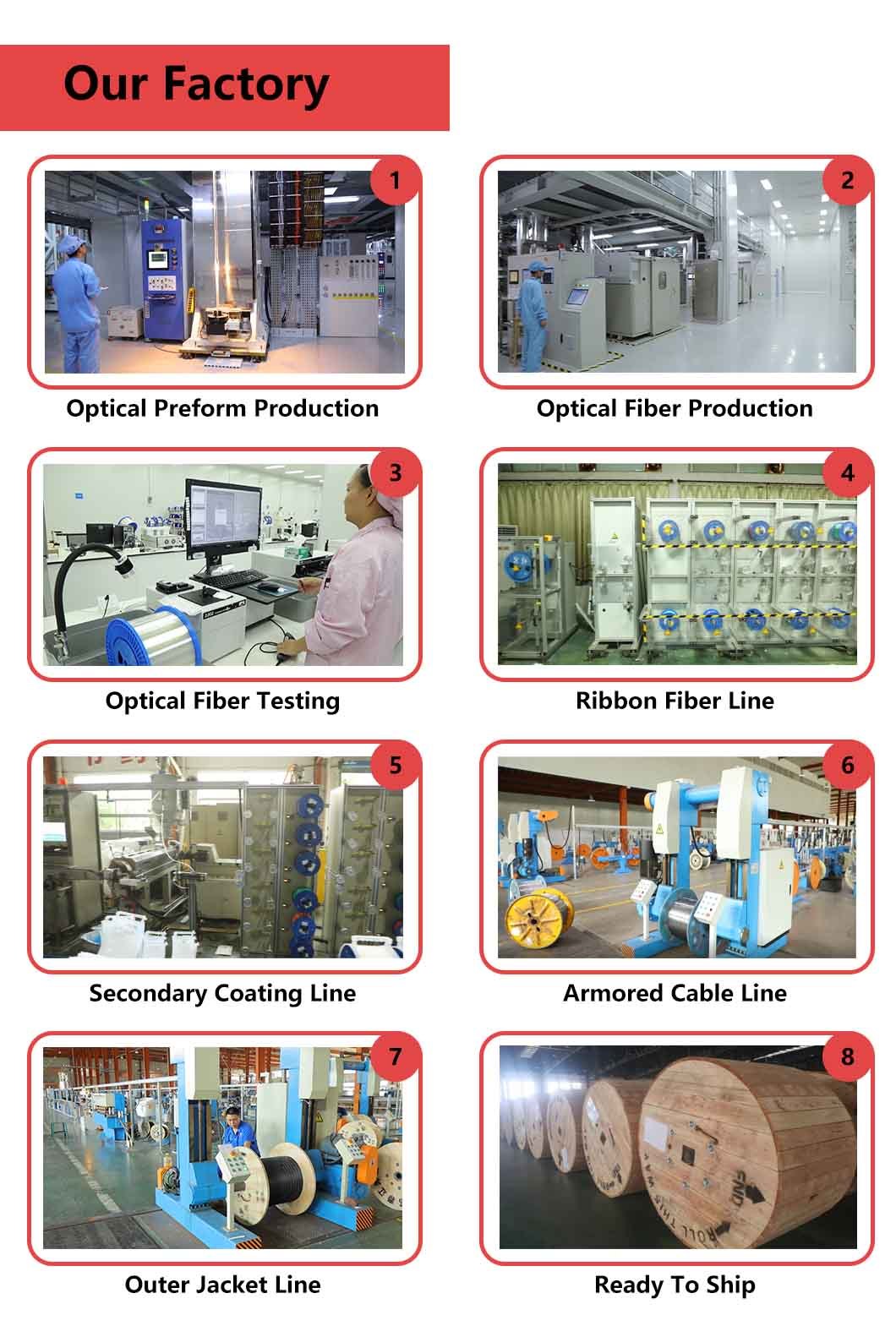

FCJ factory ADSS 24-core Single jacket All Dielectric Self-supporting Aerial fiber optic cable

- group name

- ADSS Fiber Optic Cables

- Min Order

- 1 kilometer

- brand name

- FCJ Fiber Optic Products Manufacturer

- model

- FCJ-ADSS-S80

- Nearest port for product export

- shanghai, Ningbo, Shenzhen, Guangzhou

- Delivery clauses under the trade mode

- FOB, CIF, EXW, Express Delivery

- Acceptable payment methods

- T/T, L/C, Credit Card, PayPal, Westem Union

- update time

- Wed, 11 Oct 2023 09:49:33 GMT

Paramtents

Certification RoHS, UL, CE, ISO9001, VDE, CCC

Brand FCJ OPTO TECH

Sheath Material single PE jacket

Cable Application Aerial

Loose Tube Type PBT Central Tube Type

Transport Package Wooden Drum and Carton

Specification 2KM, 3KM,4KM

HS Code 85447000

Span 80Meter

Fiber cores 2~288cores

Packging & Delivery

-

Min Order1 kilometer

Briefing

Detailed

ADSS cable is loose tube stranded. Fibers, 250μm , are positioned into a loose tube made of high modulus plastics. The tubes are filled with a water-resistant filling compound. The tubes (and fillers) are stranded around a FRP (Fiber Reinforced Plastic) as a non-metallic central strength member into a compact and circular cable core. After the cable core is filled with filling compound. it is covered with thin PE (polyethylene) inner sheath. After stranded layer of aramid yarns are applied over the inner sheath as strength member, the cable is completed with PE or AT (anti-tracking) outer sheath.

· Can be installed without shutting off the power

· Excellent AT performance, The maximum inductive at the operating point of AT sheath can reach 25kV

· Light weight and small diameter reducing the load caused by ice and wind and the load on towers and backprops

· Large span lengths and the largest span is over 1000m

· Good performance of tensile strength and temperature

· The design life span is 30 years

The actual status of overhead power lines is taken into full consideration when ADSS cable is being designed. For overhead power lines under 110kV, PE outer sheath is applied. FOR power lines equal to or over 110kV, AT outer sheath is applied. The dedicate design of aramid quantity and stranding process can satisfy the demand on variou

1、Optical

fiber performance

|

Item |

Contents |

Value |

|

Type |

SM

G.652D |

|

|

Cladding Diameter |

125.0±0.7um |

|

|

Coating Diameter |

243.0±0.7um |

|

|

Mode-Field

Diameter (MFD) |

1310nm |

9.2±0.4um |

|

1550nm |

10.4±0.6um |

|

|

Attenuation |

1310nm |

≤0.34 dB / km |

|

1383nm |

≤0.34 dB / km |

|

|

1550nm |

≤0.20dB / km |

|

|

Zero Dispersion Wavelength(λ0) |

1312±12

nm |

|

|

Zero Dispersion Slope(S0) |

≤0.092

ps/(nm2.km) |

|

|

Cable Cutoff Wavelength λcc |

≤1260nm |

|

|

Macrobend Loss |

100 turns, Φ50mm@1310nm&1550nm |

≤0.05

dB / km |

|

Proof Test |

≥9.0N,

≥1.0%, ≥100Kpsi |

|

2、Cable

identification

Fibre & Loose tube colour code

|

NO. |

1 |

2 |

3 |

4 |

5 |

6 |

|

Colour |

|

|

|

|

|

|

|

NO. |

7 |

8 |

9 |

10 |

11 |

12 |

|

Colour |

|

|

|

|

|

|

3、Cable

assembly & dimensions

|

Item |

Contents |

Unit |

Value |

|||||||

|

Fiber |

Number |

/ |

6 |

12 |

24 |

36 |

48 |

72 |

96 |

144 |

|

Loose

tube |

Material |

/ |

PBT |

|||||||

|

Number |

/ |

1 |

2 |

4 |

6 |

4 |

6 |

8 |

12 |

|

|

Ouder

diameter |

mm |

1.9 |

2.0 |

2.2 |

2.0 |

2.2 |

2.2 |

|||

|

Max

fiber per tube |

/ |

6 |

6 |

12 |

12 |

12 |

12 |

|||

|

Water

blocking material |

/ |

Jelly

compound |

||||||||

|

Central

strength member |

Material |

/ |

FRP |

|||||||

|

Ouder

diameter |

mm |

1.5 |

2.0 |

1.8 |

2.1 |

2.8 |

3.5 |

|||

|

PE

layer diameter |

mm |

/ |

/ |

/ |

/ |

3.7 |

6.4 |

|||

|

Water

blocking |

Material |

/ |

Water

blocking yarns/tape |

|||||||

|

Sterngth member |

Material |

/ |

Aramid

yarns |

|||||||

|

Number |

/ |

Determined according to the

use requirements |

||||||||

|

Outer

sheath |

Material |

/ |

HDPE |

|||||||

|

Colour |

/ |

Black |

||||||||

|

Thickness |

mm |

1.6 |

||||||||

|

Marking |

Material |

/ |

Printing

Ink |

|||||||

|

Color |

/ |

White |

||||||||

|

Way |

/ |

Ink-jet printing |

||||||||

|

Content |

/ |

(Producers+Type+Date of

production+Meter)Or Specify the

content |

||||||||

|

Drum |

Material |

/ |

Export bakelite plate drum |

|||||||

|

Optical

cable |

Ouder

diameter |

mm |

8.9 |

9.6 |

9.7 |

9.7 |

11.6 |

14.4 |

||

|

Weight |

Kg/Km |

59 |

65 |

67 |

63 |

98 |

151 |

|||

|

MAT |

KN |

1.3 |

1.5 |

1.5 |

1.6 |

2.1 |

3.0 |

|||

|

RTS |

KN |

1.8 |

2.3 |

2.1 |

2.3 |

3.3 |

4.7 |

|||

4、Mechanical

& Environmental Performance

|

Item |

Contents |

Value |

|

MAX.

Crush resistance |

Short |

1000N/100mm |

|

MIN.

Bending radius |

Operation |

12.5D |

|

Installation |

25D |

|

|

Temperature

range |

Installation |

-10℃~60℃ |

|

Operation |

-30℃~70℃ |

|

|

Storage/transportation |

-30~70℃ |

5、Main

mechanical & environmental performance test

|

Item |

Test

Method |

Acceptance

Condition |

|

Tensile

Strength IEC

60794-1-2-E1 |

Load:MAT |

Finer

strain ≤0.33% |

|

Length

of cable:≥50m |

Loss

change after test(1550nm)≤0.1dB |

|

|

Load

time:1min |

No

fiber break and no sheath damage |

|

|

Crush

test IEC

60794-1-2-E3 |

Load:Short term crush |

Loss

change after test(1550nm)≤0.1dB |

|

Load

time:1min |

No

fiber break and no sheath damage |

|

|

Impact

test IEC

60794-1-2-E4 |

Weight:0.45KG |

Loss

change (1550nm)≤0.1dB |

|

Height:1meter |

||

|

Radius:12.5mm |

No

fiber break and no sheath damage |

|

|

Times:≥5 |

||

|

Repeated

Bending IEC

60794-1-2-E6 |

Bending

radius:≤20D |

Loss

change (1550nm)≤0.1dB |

|

Wdight:150N |

No

fiber break and no sheath damage |

|

|

Times:30 |

||

|

Water

penetration IEC

60794-1-2-F5 |

Height

of water:1m |

No

water leak from the cable core of the opposite end |

|

Sample

length:3m |

||

|

Time:24h |

||

|

Temperature

cycling IEC

60794-1-2-F1 |

Temperature:-40℃~70℃ |

Loss

change (1550nm)≤0.1dB |

|

Time

of each step:12h |

No

fiber break and no sheath damage |

|

|

Number

of cycle:2 |

6、Packing

---Each single cable length been wound on an

Export

bakelite

plate drum or pure wooden drum;

---Standard drum length is 4000m or Specify

the length;

---At least 3m of cable inner end should be

reserved for testing;

---Covered by plastic buffer sheet;

---Sealed by strong wooden drum