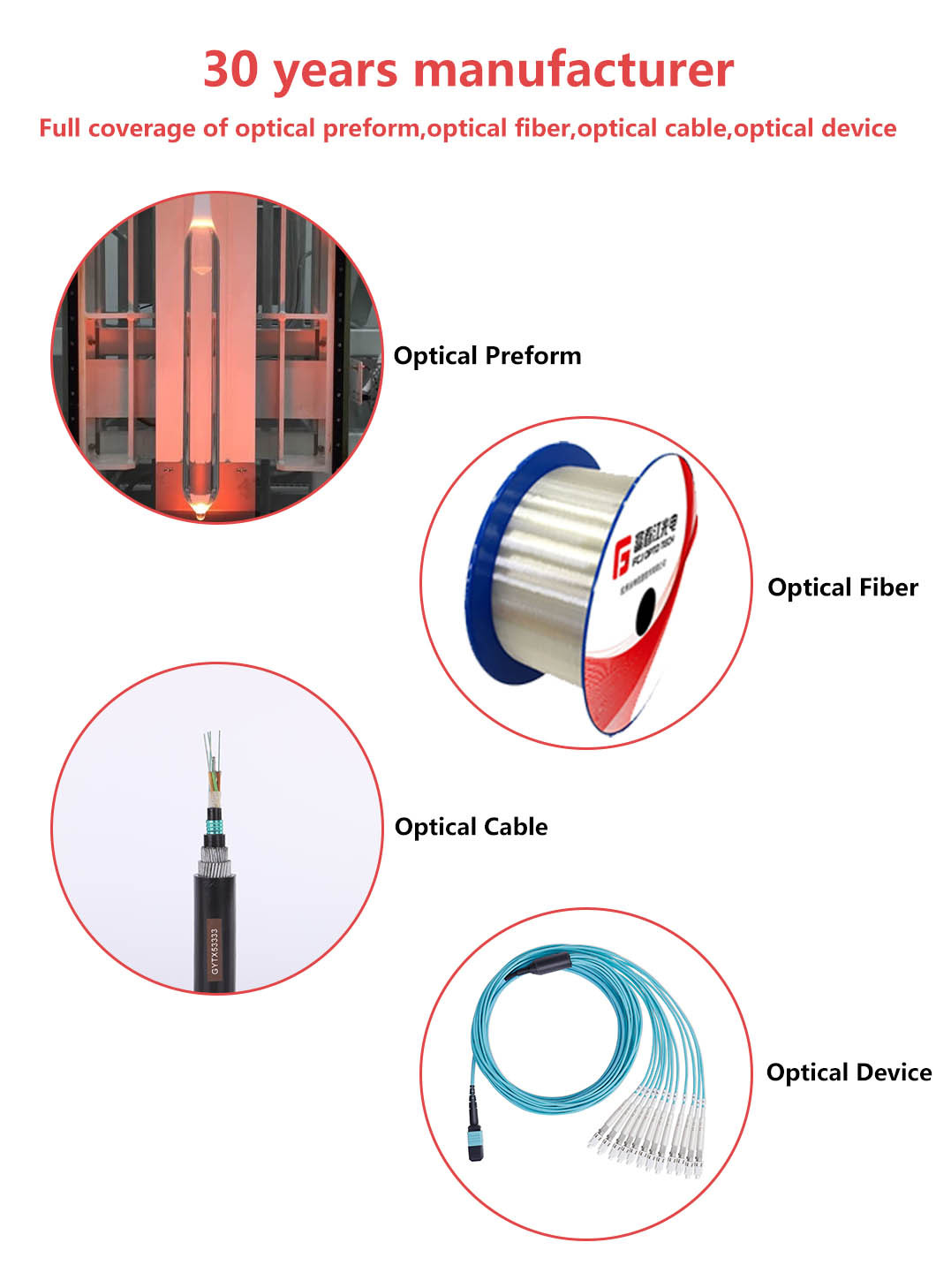

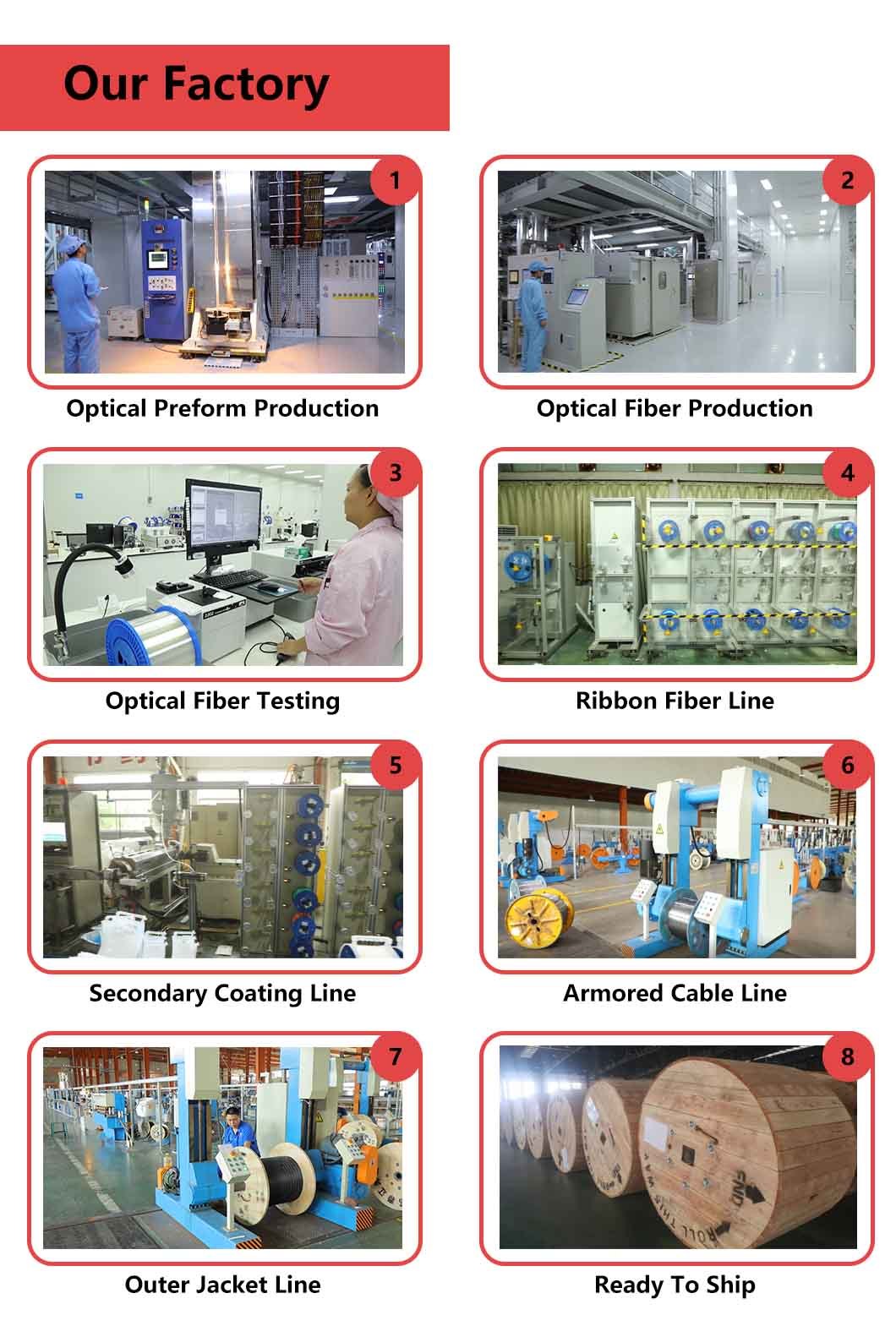

FCJ factory Outdoor GJFJU-1F aerial fiber optic cable TPU jacketed

- group name

- Indoor Fiber Optic Cables

- Min Order

- 1 kilometer

- brand name

- FCJ Fiber Optic Products Manufacturer

- model

- GJFJU-1F

- Nearest port for product export

- shanghai, Ningbo, Shenzhen, Guangzhou

- Delivery clauses under the trade mode

- FOB, CIF, EXW, Express Delivery

- Acceptable payment methods

- T/T, L/C, Credit Card, PayPal, Westem Union

- update time

- Wed, 27 Sep 2023 14:26:06 GMT

Paramtents

Fiber Type G652D/G657

Operating Temperature -40°C to + 70°C

Installation Aerial

Transport Package Wooden Drums or as Per Customers′ Requests

Packging & Delivery

-

Min Order1 kilometer

Briefing

Detailed

GJFJU-1F Outdoor single core tight-buffered aerial fiber optic cable is a single core optical fiber that tight buffered and surrounded by aramid yarn strength member (or glass yarn) and jacketed with TPU,cable dia. 3.0~4.8mm or customized. Cable span around 20~30KM This specification covers the design requirements and performance standard for the supply of optic fiber cable in the industry. It also includes FCJ premium designed cable with optical, mechanical and geometrical characteristics.

|

Cable type |

Application |

|

GJFJU(Tight sheath optical cable)--1 |

Self-supporting aerial installation |

FCJ fiber optic cable has excellent optic transmission and physical performance, to meet customer’s requirements.

Reliability

Initial and periodic qualification tests for raw material and cable product are performed to assure the cable’s performance and durability in the field environment.

ITU-T G.652 | Characteristics of a single-mode optic fiber |

IEC 60794-1-1 | Optic fiber cables- part1-1-Generic specification-General |

Optic fiber cables- part1-2-Generic specification-Basic optic cable test procedure-Mechanical test methods | |

IEC 60794-1-22 | Optic fiber cables- part1-2-Generic specification-Basic optic cable test procedure-Environmental test methods |

IECA S-104-696 | Standard for indoor-outdoor optic fiber cable |

Working Condition

Storage temperature: -40℃~+70℃

Operation temperature: -40℃~+70℃

Installation temperature: 0℃~+60℃

Static: 10D

Dynamic: 20D

D is the out diameter of the cable

Optic fiber cables supplied in compliance with the specifications can be capable of withstanding the typical service condition for a period of twenty-five (25) years without detriment to the transmission or operation and maintenance characteristics of the cable.

Optic properties of the SM fiber are achieved through a germanium doped silica based core with a pure silica cladding which meets ITU-T G.657, UV curable acrylate protective coating is applied over the glass cladding to provide the necessary maximum fiber lifetime.

Geometrical, optic and mechanical characteristics of fiber in cable as the following table:

Category | Description | Specification | |

|

| Before cable | After cable |

Geometrical Characteristics | Cladding diameter | 125.0 ±0.7mm | |

| Cladding non-circularity | £ 0.7 % | |

| Core concentricity error | £ 0.6mm | |

| Coating diameter | 243± 7mm(Before Colored) 250 ± 15 mm (Colored) | |

| Coating/cladding concentricity error | £10mm | |

Optic Characteristics | Mode field diameter at 1310 nm | 8.8±0.4mm | |

| Point discontinuity | £ 0.04dB | |

| Attenuation at 1310 nm | £0.5dB/km | |

| Attenuation at 1550 nm | £ 0.5dB/km | |

| Dispersion in the range of wavelength 1550 nm | £18 ps/(nm·km) | |

| Dispersion in the range of wavelength 1625 nm | £ 22 ps/(nm·km) | |

| Zero dispersion wavelength | 1300 – 1324 nm | |

| Zero dispersion slope | £0.092 ps/(nm2·km) | |

| Cable cut-off wavelength | £1260 nm | |

| Polarization mode dispersion individual fiber | £0.1 ps/Ökm | |

| Polarization mode dispersion design link value (M=20, Q=0.01%) | £ 0.06ps/Ökm | |

| Macro-bend loss (100 turns, 30mm radius, 1550/1625nm) | £ 0.15 dB | |

Mechanical Specification | Proof stress level | ³100kpsi (0.69 GPa) | |

| Coating strip force(peak value) | 1.3~8.9N | |

| Fiber curl (Radius) | ³ 4 m | |

Fiber color code | 1 | 2 |

3

|

4

|

5

|

6

|

Blue | Orange |

Green |

Brown |

Slate |

White* |

|

7 | 8 |

9

|

10

|

11

|

12

|

|

Red | Black |

Yellow |

Purple |

Pink |

Aqua |

*The Color also be natural

The optic fiber adopts G.657 series coated optic fiber, and a tight jacket layer composed of a suitable thermoplastic material is added to the outside. It has a mechanical buffer protection effect on the coated optic fiber and is easy to strip from the light;

The optic cable adopts aramid tow or the glass yarn is used as a strengthening member, and they are evenly twisted in layers or placed longitudinally outside the optic fiber tight jacket;

The optic cable is extruded with a layer of circular polyurethane (TPU) sheath outside the strengthening member.

TYPE | Unit | Description | |||

Tight-buffered fiber | Optical fibre | / | G.657 | ||

| Material | / | Riser rated thermoplastic | ||

| Diameter (mm) | mm | 0.9±0.05 | ||

Strengthening Material | Material | / | Aramid | Glass yarn | |

| Dosage | Kg | Meet 800N (or required) short-term tension | Meet 500N (or required) short-term tension | |

Sheath | Material | / | Polyester elastomer TPU | Polyester elastomer TPU | |

| Diameter | mm | 3.0±0.2 | 4.8±0.2 | |

| Thickness | mm | 0.5±0.1 | 0.9±0.2 | |

| Color | / | Black | ||

Cable weight Approx | Kg/Km | 8 | 30 | ||

Item | Contents | Value | |

Max. tensile load | Short term | 800N (or required) | 500N (or required) |

Max. crush resistance | Short term | 500 N/100mm | 500 N/100mm |

Min. bending radius | Installation | 20 x cable diameter | |

| Operation | 10 x cable diameter | |

Temperature range | Operation | -20℃ ~ +60℃ | |

| Installation | -20℃ ~ +60℃ | |

| Storage/transportation | -5℃ ~ +40℃ | |

Item | Test Method | Acceptance Condition |

Tensile Strength IEC 60794-1-2-E1 | - Load: Short term tension - Length of cable: ≥ 50m - Load time: 1min | - Loss change £ 0.05dB@1550nm after test. - No fiber break and no sheath damage. |

Crush Test IEC 60794-1-2-E3 | - Load: Short term crush - Load time: 1min | - Loss change £ 0.05dB@1550nm after test. - No fiber break and no sheath damage. |

Impact Test IEC 60794-1-2-E4 | - Radius: 12.5 mm - Points of impact: 5 - Times of per point: 1 - Impact energy: 1J | - Loss change £ 0.05dB@1550nm after test. - No fiber break and no sheath damage. |

Cable bend IEC 60794-1-2-E11 | - Diameter of mandrel:20 x OD - Number of cycles:20 | - Loss change £ 0.05dB@1550nm after test. - No fiber break and no sheath damage. |

Torsion IEC 60794-1-2-E7 | - Length:250mm - Twist angle: ±180° - No. of cycle: 20 | - Loss change £ 0.1dB@1550nm after test. - No fiber break and no sheath damage. |

Temperature Cycling IEC 60794-1-2-F1 | - Temperature:-20℃~+60℃ - Time of each step: 12h - Number of cycle: 3 | - Loss change £ 0.05dB/km@1550nm after test. - No fiber break and no sheath damage. |

Remark: “No attenuation changes” is considered as the attenuation changes ≤ 0.05 dB.

Cable Sheath Marking:

Unless otherwise specified, the cable sheath marking shall be as follows:

Color: White

Contents: FCJ OPTO TECH., the year of manufacture, the type of cable, cable number, length marking

Interval: 1±0.2% m ( or customized)

Cable Length

Reel length: 2 km/drum.

Cable Drum

The cables are packed in fumigated wooden drums.

Cable Packing

Both cable ends are protected against water penetration and firmly secured to the drum, so the cable cannot move and the turns cannot slide when it is moved, handled or laid. The inner end has around 3 meters of accessible length to perform reception tests.

Other packing method is also available according customer’s requirement.