FCJ factory 9.5/125 μm sm optical fiber Bend Insensitive Single-Mode Fiber

- group name

- Single Mode Optical Fiber

- Min Order

- 1 roll

- brand name

- FCJ Fiber Optic Products Manufacturer

- model

- Optical Fiber G.657A2

- Nearest port for product export

- shanghai, Ningbo, Shenzhen, Guangzhou

- Delivery clauses under the trade mode

- FOB, CIF, EXW, Express Delivery

- Acceptable payment methods

- T/T, L/C, Credit Card, PayPal, Westem Union

- update time

- Wed, 27 Sep 2023 09:04:18 GMT

Paramtents

Fiber Type G.657.A1

Operating Temperature -40°C to + 70°C

Installation Aerial/Direct Buried/Duct

Packging & Delivery

- 61cm x45cm x30cm

-

Min Order1 roll

Briefing

The optic fiber complie with or exceed the technical specifications in ITU-T G.657.A1/A2/B2. Optical Fiber G657A2 .

Detailed

Type

Bend Insensitive Single-Mode Optical Fiber G.657.A2

Standard

The fiber complie with or exceed the technical specifications in ITU-T G.657.A1/A2/B2.

Features

- Minimum bend radius 7.5mm, superior anti-bending property;

- Fully compatible with G.652 single-mode fiber. Full band (1260~1626nm) transmission;

- Low PMD for high bit-rate and long distance transmission. Extremely low micro-bending attenuation, applicable for all optical cable types including ribbons;

- High anti-fatigue parameter ensures service life under small bending radius.

Application

All cable constructions, 1260~1626nm full band transmission, FTTH high speed optical routing, optical cable in small bend radius, small-size optical fiber cable and device, L-band.

Technical Specifications

| Attributes | specification | |||

| Dimensional Specifications | Cladding Diameter | 125.0±0.7 um | ||

| Cladding Non-Circularity | ≤0.7% | |||

| Coating Diameter | 243±7 um | |||

| Coating-Cladding Concentricity | ≤10 um | |||

| Coating Non-Circularity | ≤6 % | |||

| Core-Clad Concentricity | ≤0.5 um | |||

| Fiber curl (radius) | ≥4 m | |||

| Delivery length | 2.1-50.4( km/reel) | |||

Optical Specifications Optical Specifications | Mode-Field Diameter (MFD) | @1310nm | 8.6±0.4 um | |

| @1550nm | 9.8±0.6 um | |||

| Attenuation | @1310nm | ≤0.35 dB / km | ||

| @1383nm | ≤0.35 dB / km | |||

| @1550nm | ≤0.21 dB / km | |||

| @1625nm | ≤0.23dB / km | |||

| Attenuation VS. Wavelength | @1285-1330nm, Ref. λ@1310nm | ≤0.03 dB / km | ||

| @1525-1575nm, Ref. λ@1550nm | ≤0.02 dB / km | |||

| Point Discontinuity | @1310nm | ≤0.04 dB | ||

| @1550nm | ≤0.04 dB | |||

| Polarization Mode Dispersion(PMD) | Maximum Individual Fiber PMD | ≤0.1 ps/(km1/2) | ||

| PMD Link Design Value (M=20, Q=0.01%) | ≤0.06 ps/(km1/2) | |||

| Typical Value | 0.04 ps/(km1/2) | |||

| Zero Dispersion Wavelength(λ0) | 1312±12 nm | |||

| Zero Dispersion slope(S0) | ≤0.092 ps/(nm2.km) | |||

| Dispersion | 1550nm | ≤18 ps/(nm.km) | ||

| 1625nm | ≤22 ps/(nm.km) | |||

| Cable cutoff wavelength λcc | ≤1260 nm | |||

| Mechanical Specifications | Proof test | ≥9.0N, ≥1.0%, ≥100Kpsi | ||

| Dynamic stress corrosion susceptibility parameters Nd | ≥20 | |||

| Coating strip force | Average | 1.7 N | ||

| Peak | 1.3-8.9 N | |||

| Macrobending loss (dB) | 1 turn, Φ15mm@1550nm&1625nm | ≤0.5 dB, ≤1 dB | ||

| 1 turn, Φ20mm@1550nm&1625nm | ≤0.1 dB, ≤0.2 dB | |||

| 10turns, Φ30mm@1550nm&1625nm | ≤0.03 dB, ≤0.1 dB | |||

| Environmental Specifications | Temperature Dependence (-60ºC to +85ºC@1310nm&1550nm&1625nm) | ≤0.05 dB / km | ||

| Temperature Humidity Cycling(-10ºC to +85ºC, at 85%RH@1550nm&1625nm) | ≤0.05 dB / km | |||

| Water Immersion(23±2ºC, 30 days@1550nm&1625nm) | ≤0.05 dB / km | |||

| Dry Heat Soak(85±2ºC, 30 days@1550nm&1625nm) | ≤0.05 dB / km | |||

| Damp Heat(85±2ºC, at 85%RH, 30 days@1550nm&1625nm) | ≤0.05 dB / km | |||

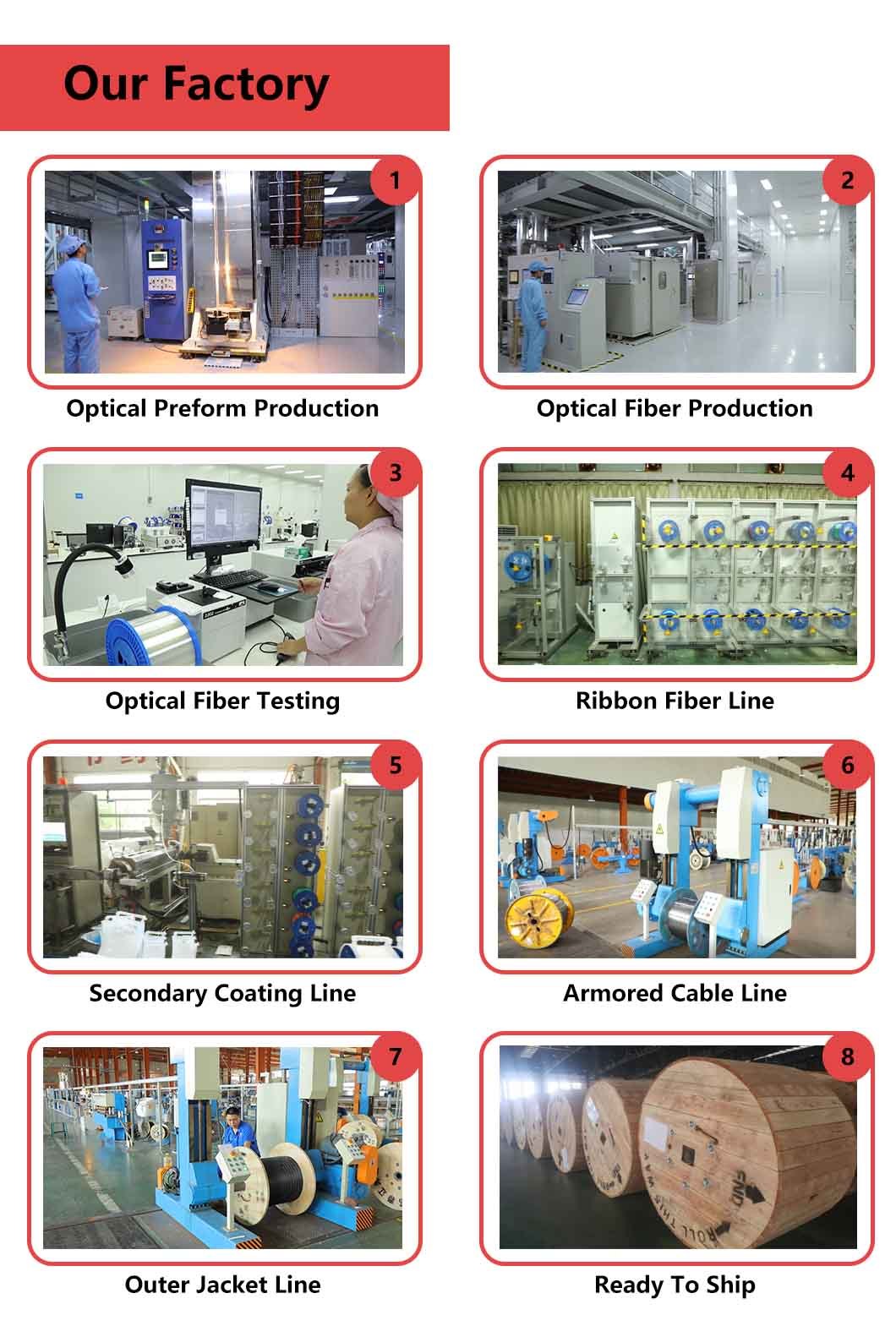

The company produces and tests optical fiber independently, all qualified fibers meet the requirements of technical specifications.

Packaging and storage