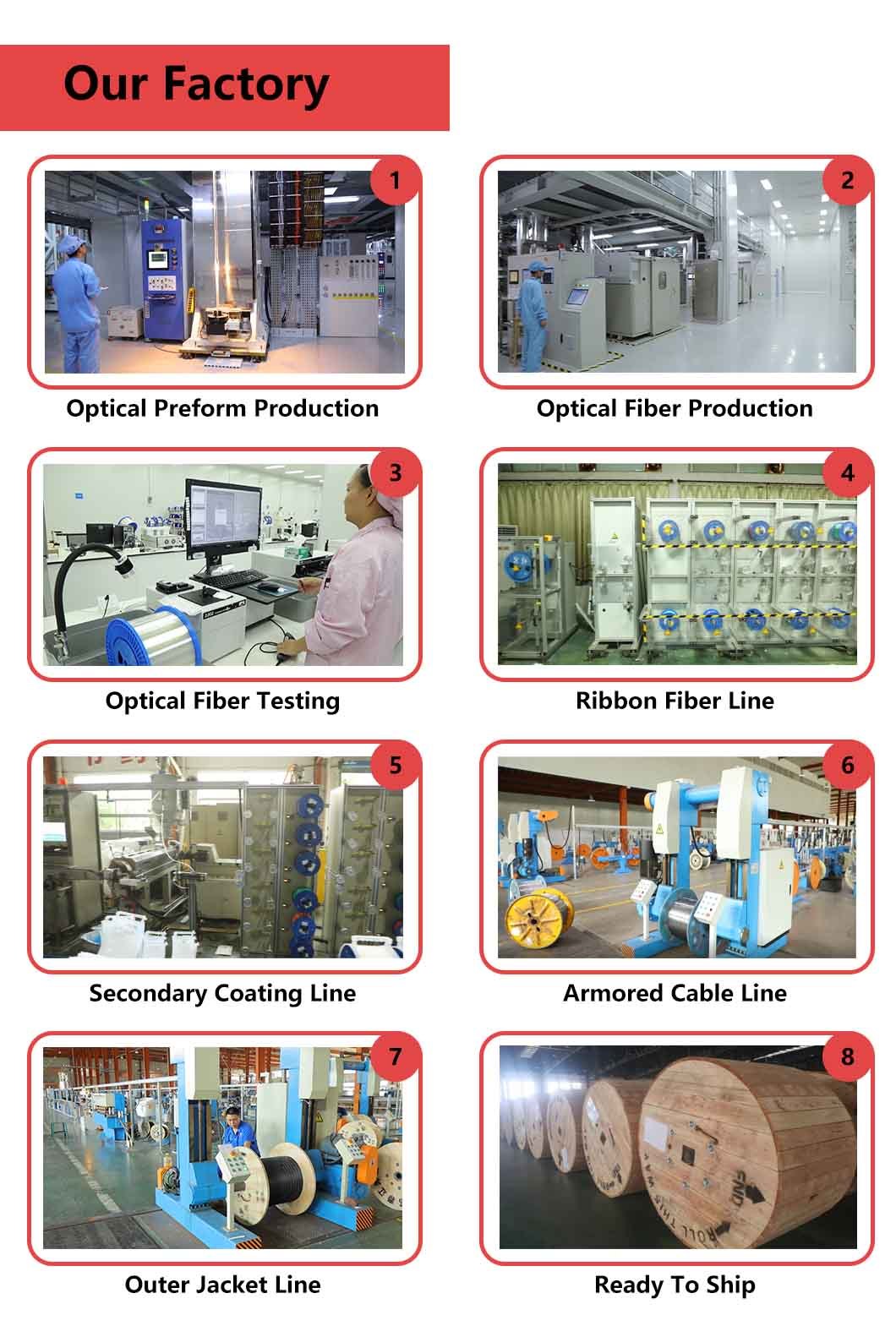

FCJ factory Mini air-blown mini figure 8 fiber optic cable Air Blown Fiber Optic Cable

- group name

- Micro Air Blown Fiber Optic Cables

- Min Order

- 1 kilometer

- brand name

- FCJ Fiber Optic Products Manufacturer

- model

- Mini air-blown cable

- Nearest port for product export

- shanghai, Ningbo, Shenzhen, Guangzhou

- Delivery clauses under the trade mode

- FOB, CIF, EXW, Express Delivery

- Acceptable payment methods

- T/T, L/C, Credit Card, PayPal, Westem Union

- update time

- Wed, 27 Sep 2023 10:39:01 GMT

Paramtents

Number of Conductors ≥ 10

Fiber Type G652D/Multimode

Armored Yes

Operating Temperature -40°C to + 70°C

Installation Aerial/Direct Buried/Duct

Transport Package Wooden Drums or as Per Customers′ Requests

Packging & Delivery

-

Min Order1 kilometer

Briefing

Detailed

Mini center tube type air-blown fiber optic cable is coloring 2-24 core fiber placed in the bundle tube, the outer skin extruded a layer of high-density polyethylene outer sheath.

● Special composite material loose casing to reduce low temperature casing retraction.

● Precise control of fiber residual length, stable performance of optical cable.

●Unique process control to eliminate sheath wrinkling in air blowing.

●High density polyethylene outer sheath to improve air blowing distance.

IEC 60794-5、IEC 60794-1-2 or D/T 1460-2006

G.652 | G.655 | 50/125μm | 62.5/125μm | ||

Attenuation | @850nm | ≤3.0 dB/km | ≤3.0 dB/km | ||

@1300nm | ≤1.0 dB/km | ≤1.0 dB/km | |||

@1310nm | ≤0.36 dB/km | ≤0.40 dB/km | |||

|

@1550nm |

≤0.22 dB/km |

≤0.23dB/km |

|||

Bandwidth (Class A) | @850nm | ≥500 MHz·km | ≥200 MHz·km | ||

|

@1300nm |

≥1000 MHz·km | ≥600 MHz·km | |||

|

Numerical Aperture |

0.200±0.015NA | 0.275±0.015NA | |||

|

Cable Cut-off Wavelength |

≤1260nm |

≤1480nm |

|||

Mini Cable Type | GCYFXY-xxF(MTE +Outer diameter) | ||||

MTE1.8 | MTE2.0 | MTE2.3 | MTE2.5 | MTE2.8 | |

Fiber Count | 2~4 | 2~4 | 6~12 | 2~12 | 14~24 |

HDPE Outer Sheath Thickness | Nominal:0.20mm,Mini: 0.15mm | ||||

Nominal Outer Diameter | 1.8mm | 2.0mm | 2.3mm | 2.5mm | 2.8mm |

Approximate Weight | 2.6 kg/km | 4.0 kg/km | 5.0 kg/km | 6.0 kg/km | 7.0 kg/km |

Attenuation (single-mode fiber) | 1310nm/1550nm≤0.35/0.22dB/km | ||||

Max. Pulling Force | 40N | 40N | 50N | 60N | 60N |

Max. Squeeze Force | 600N/100mm | ||||

Mini Permissible Static / Dynamic Bending Radius | 10x/20x O.D. of fiber optic cable | ||||

Temperature Range | Storage -30~+60℃; Installation -10~+40℃; Operation -20~+50℃ | ||||

Fiber optic cable life (valuation) | 25 YEARS | ||||

Mechanical performance

Items | Test Reference Standards | Test Results | Remarks | |

Tension | IEC 60794-1-2-E1 | Fiber Strain(%) | Accessory Decay(dB) | Short-term test tension is the maximum tension. Long-term test tension is 1/3 of the maximum tension |

Short-term ≤0.3 | Short-term:≤0.1, | |||

Flattening force | IEC 60794-1-2-E3 | Short-term crushing force: additional attenuation ≤ 0.05. Long-term crushing force: no significant. After stress removal, no visible residual additional attenuation of the fiber, the No visible cracking on the sheath surface | Short-term test pressure:600N Long-term test pressure: 200N | |

Repeated bending Test | IEC 60794-1-2-E6 | After testing: no visible residual accessory attenuation of the fiber. No visually visible cracking of the sheath | Bending radius = 20 times the diameter of the micro cable | |

|

Load = 15N |

||||

Bending times: 25 | ||||

Torsion test | IEC 60794-1-2-E7 | After the test: no fiber breakage and no visually visible cracking of the sheath. After stress removal, no obvious residual additional attenuation | Turning angle: ±180º | |

Load = 15N | ||||

Number of torsions: 5 | ||||

Winding test | IEC 60794-1-2-E11A | After the test: no fiber breakage and no visually visible cracking of the sheath | Mandrel diameter = 20 times the diameter of the micro cable | |

|

Number of tightly wound turns = 10 |

||||

|

Number of cycles = 5 |

||||

|

All the above results are tested at 1550nm wavelength |

||||

Blowing Performance

|

Test Equipment |

Typical air delivery lengths and pipe types suitable for air delivery |

||

|

Polimente: PRM-196 , PR140 etc. Air pressure: 13bar |

Fiber Count |

Microtube type |

Microtube type |

|

2~12 |

800m |

1500m |

|

|

14~24 |

500m |

1500m |

|

Environmental Characteristics

|

Items |

Test Method |

Indicators to be achieved by the test |

Temperature Performance | IEC 60794-1-2-F1 | Additional attenuation of fiber (1550nm) |

|

≤0.1 dB/km |

||

|

Water penetration performance |

IEC 60794-1-2-F5B |

1m water height, 3m cable, test time 24 hours No water seepage from the other end of the micro cable |

|

Drip performance |

IEC 60794-1-2-E14 |

Microcables are maintained at an ambient temperature of 70°C for 24 hours No filler compound drops out of microcables |